Roster Alerts

Understand how your operators are performing during shifts to better provide feedback about accomplishments and flag areas to improve.

Challenges

Opportunities

Operator Habits

Operator Habits

Our algorithms study the vital signs of the equipment and correlate it with user information and GPS data to obtain key information about operator behavior.

Shift KPIs

Shift KPIs

Our displays show real time indicators about operators, including other production KPIs affected by their performance.

Industrial Hardware

Industrial Hardware

The display technology implemented on site is protected from dust and water and can be viewed under direct sunlight to maximize performance.

Real Time Notifications

Real time notifications

Managers can take action when operators carry out bad practices that can damage equipment or roads and affect company performance.

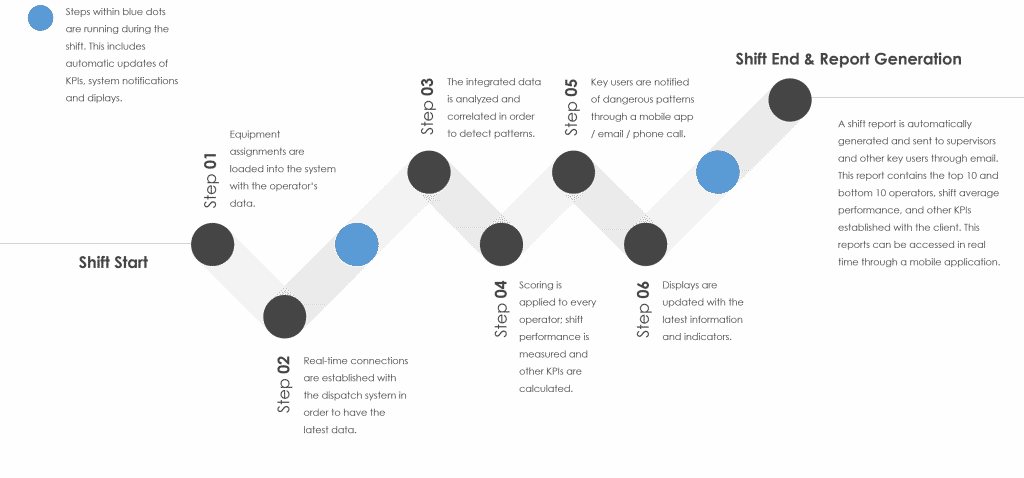

How does it work?